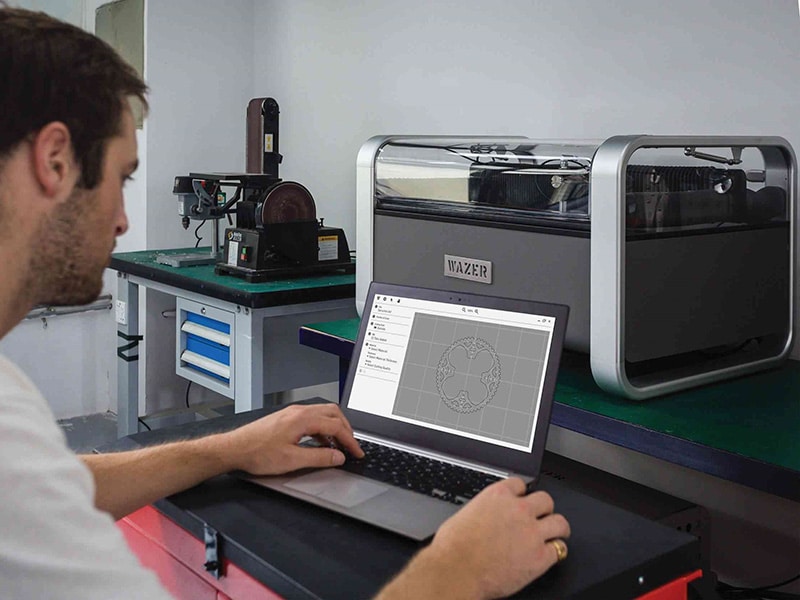

Soon available through Hare & Forbes Machinery House, the Wazer desktop CNC waterjet cuts hard and soft materials with digital precision.

Waterjet cutters have been around for a long time, however their size and cost has put them out of the reach of individuals or small business.

But the new Wazer desktop waterjet is designed to change that, using a high velocity jet and a combination of high-pressure water and abrasive particles to cut through both hard and soft materials.

The Wazer small format waterjet can cut through sheets of any material including metal, stone, ceramic, composites, plastic, rubber and foam.

Users have been attracted by its simplicity of setup which is connection to standard electricity, water and drainage.

The unit’s compact size fits in any workspace and brings professional-grade fabrication into any workshop. It is ideal for on demand cutting of custom parts and its in-house capabilities reduce costly outsourcing.

Wazer has been in high demand by small manufacturing businesses, research and development facilities, universities and technical departments where it is used for prototyping, manufacturing, fine art and instruction.

The waterjet was developed by co-founders Nisan Lerea and Matthew Nowicki during their time as students at the University of Pennsylvania, where both were involved in the students’ Formula SAE Team, which built a new racecar every year to race at an intercollegiate competition.

“I would go on to spend hundreds of hours in Penn’s machine shop, CNC-milling metal parts for the race car, for research labs, or for my own coursework,” Lerea says.

Lerea says the engineers would normally try to save time by designing parts that could be laser cut – with the downside of this being that they could only use parts made in acrylic or MDF.

Tasked by a professor to build a small waterjet for the assigned year-long design project, by May 2012 the students had built their first small-scale waterjet, capable of cutting through aluminium 6.3mm thick and steel 3mm thick.

By 2015 Lerea and Nowicki were working on the project full time, and in January 2016 they moved temporarily to Shenzhen, China to join the Hax Accelerator, where they developed the business and refined the design and engineering of Wazer.

Today, the Wazer team comprises mechanical, electrical and manufacturing engineers who collectively have led the designs of multiple products both at start up and large companies.

Further details and full specifications available at https://www.machineryhouse.com.au/w08720