Two filling and sealing solutions for pre-made cups – the new Ampack FCL aseptic linear machine and the upgraded Osgood rotary model – will be displayed by Bosch Packaging Technology at Dusseldorf’s Interpack 2017 expo in May.

Bosch says the equipment has been developed to address the key market requirements for dairy producers, such as hygienic operation, low and high output, compact footprint and ease of use.

“The two filling technologies – rotary and linear – complement our existing portfolio for the whole output range and help us respond to various production needs,” Ampack sales managing director Markus Schlumberger says.

“Our goal at Interpack is also to present the extended capacity of our services after adding Osgood to the Bosch family.”

Safety first

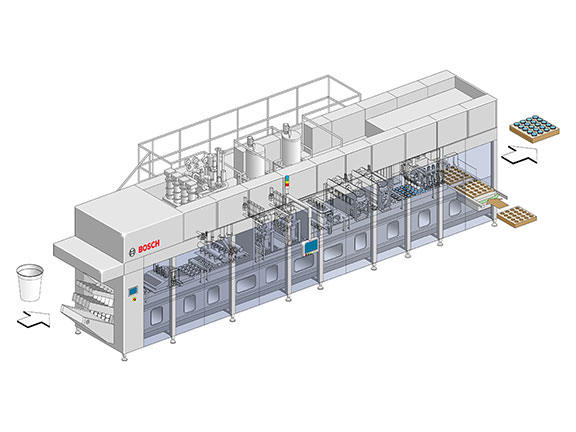

Ampack’s new FCL 3080 A aseptic linear filling and sealing machine is designed to enhance product safety in the production of dairy, baby food and clinical nutrition lines.

It features a smaller aseptic chamber which improves product control, Bosch says, and minimises the risk of food contamination.

The machine chain is also kept outside of the aseptic chamber, limiting bacterial build-up and maintenance needs.

In terms of flexibility, the eight-lane linear filler handles two different cup formats – ranging from 75mm to 95mm in diameter – at speeds of up to 20,000 cups per hour.

The machine fills a broad range of products with particles up to 22mm in diameter and offers ultra-clean or aseptic hygienic executions

“It is an ideal solution for products requiring a longer shelf life outside the cooling chain – from 4 to 6 weeks or up to 12 months, the highest level available on the market,” Bosch says.

Compact hygiene

For dairy and other food applications (such as hummus or potato salads), Bosch has upgraded its existing Osgood rotary series.

The machine now handles smaller cups at speeds of up to 9,600 products an hour on four lanes, and is described by the company as “a good alternative for producers with limited space with regards to their production capacity”.

Available in both clean and ultra-clean execution, the machine can fill a range of different pack styles depending on the final application – for example, round and square cups with trays, seals with pre-die cut foils or roll stock film.

“The rotary filler is also equipped with a new harmonized pump design, developed by experts from Bosch’s food business unit, which provides higher filling accuracy and easier interchangeability between different machines,” the company says.

“The rotary filler ensures easier and faster changeovers (in less than 15 minutes) thanks to new servo motors, enabling quick and easy adjustments to the set-up.”