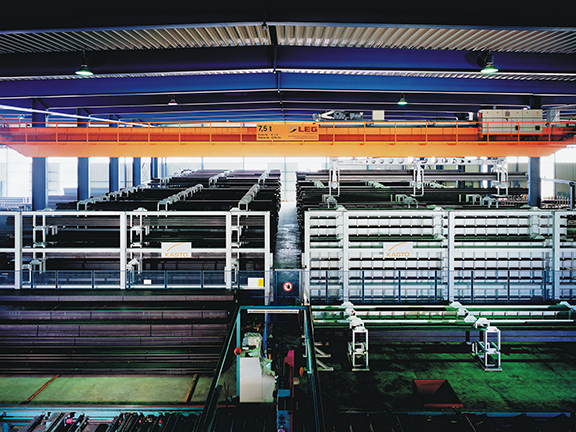

The new Kasto Unibloc is a compact stacking cradle system for transporting and storing bar stock, sheet metal and other bulky goods with low to medium access frequencies.

The German saw and storage company says the system is a cost-effective alternative to a highly dynamic, fully automatic — and expensive — bar storage system.

Simple to use and capable of handling material of 3m to 24m in length, the Unibloc system is designed to provide quick access to stored goods and restack them efficiently, Kasto adds.

“Rational storage, order picking and processing of profiles, tubes and beams often plays an important role in steel trading companies and metal processing centres,” it says.

“Here, traditional floor storage has distinct disadvantages with regard to speed and storage density, while on the other hand fully automatic storage systems are expensive to buy and are simply too big for many users.

“With the Unibloc stacking cradle system, we therefore have an interesting alternative in our range for all storage needs when low to medium access frequencies are required.”

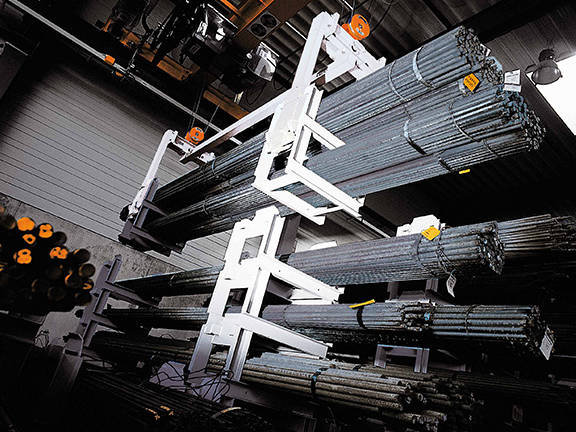

The system stores tubes, bars, steel beams and other bar stock on sturdy, precision-welded cradle pairs which have a working load of up to 6 tonnes and can be stacked on top of one another.

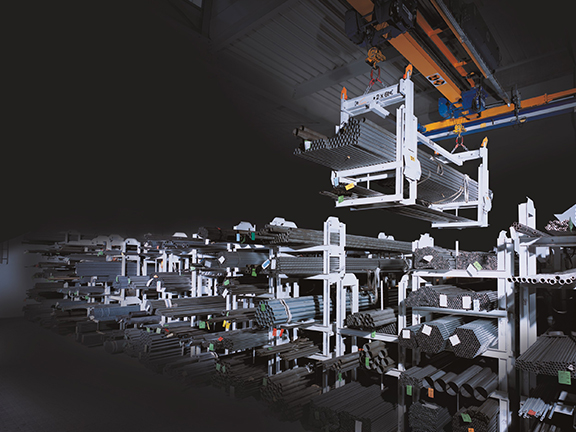

A spreader beam with patented gripper arms transports and restacks up to three layers of material at the same time, depending on the model. The beam can be moved manually by means of a stacker, automatically by means of a gantry crane or overhead crane, or by means of a magnetic lift.

Katso says that the stacking cradle system is easy and safe to operate.

“For example, indicator lamps show when the stacking cradles are reliably detected,” it says. “This makes the job easier and ensures economic restacking. The fold-in grippers can even remove laterally stored materials from adjacent pairs of cradles without difficulty.”

The automatic version uses Katso’s Inventory Control Computer to automatically manage materials and storage locations, and organise storage, restacking and removal tasks.

Continuous inventory management means the operator is able to monitor stocks at all times and, if necessary, the organisation of the store can be optimised without the need for personnel at any time of the day or night.