The CSIRO has launched its FloWorks Centre for Industrial Flow Chemistry — a process which produces chemicals in a steady stream rather than in batches — in the Melbourne suburb of Clayton.

The scientific research agency says the centre will provide cutting-edge research into flow chemistry capability, making it more accessible to the chemical manufacturing industry.

The process offers a cleaner, smarter and more efficient way of making chemicals, according to FloWorks director and CSIRO manufacturing senior research scientist Dr Christian Hornung.

“The benefits of using the flow process include reduced reaction times and plant space, which equate to less energy cost, more efficient processes, reduced waste and a much safer environment,” he says.

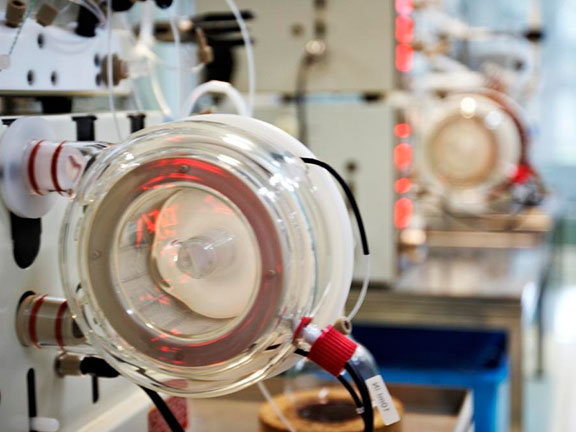

While more traditional chemical manufacturing uses batch methods, in flow chemistry the starting materials are fed into a reactor where the chemical reaction takes place in a continuous stream. The CSIRO says it’s a method that, in many cases, has proven to be a more efficient and cost effective way of producing chemicals.

Multi-stage processing, which eliminates the need for manual handling of chemicals in between steps, greatly improves safety, while in-line purification makes the system more streamlined.

Smart monitoring and online analysis is used to automate the manufacturing process.

The purpose-built 410-square-metre facility will be housed at CSIRO’s Clayton site in Melbourne’s south east. Incorporating all of CSIRO’s flow chemistry equipment, its capabilities will range from small-scale discovery tools to large-scale industrial reactors.

Boron Molecular’s Zoran Manev uses flow chemistry at his Noble Park plant to manufacture fine chemicals for Australian and international pharmaceutical and materials science clients.

“CSIRO helped us integrate flow chemistry into our operations,” Manev says. “We use our unit to develop a number of processes or convert them from batch to flow.

“Flow chemistry enables us to make purer molecules, so we have fewer side products and fewer issues when we scale up to manufacture from small scale to larger tonne lots.

“With flow we’re using far less solvents and energy and discarding far less waste material into the environment than we would otherwise,” Manev adds.

Hornung says the new collaborative FloWorks space would generate greater engagement with industry and other research bodies by offering a unique, complete package from early discovery to industrial scale-up and tech transfer.

“I see flow technology eventually being taken up by chemical manufacturers in all areas,” he says.