Our resident ‘Bush Mechanic’ provides a comprehensive guide to buying a welder for your farm workshop.

There’s no single machine that meets all the welding needs on the farm. Here are some considerations for choosing one welding process over another.

The first three candidates here are arc welders that join two metals by generating an electric arc between a covered metal electrode and the base metals.

The heat produced by the arc melts the metal which mixes with the molten deposits of the coated electrode or the wire and gas shield.

ARC WELDERS

|

First up, the stick welder, the old stand-by, is usually the cheapest welder and arc welding technique.

Technically called shielded metal arc welding, stick welding works better than the other processes on dirty or rusty materials and in windy conditions.

Stick weld times are comparatively slower, since the consumable electrodes must be frequently replaced and because slag, the residue from the flux, must be chipped away after welding.

Shellfish can make you a better welder! As for technique, if you’re just learning the stick process, remembering these five points will improve your welding technique. Simply think ‘CLAMS’: Current setting, Length of arc, Angle of electrode, Manipulation of the electrode and Speed of travel.

What are the advantages or disadvantages of AC vs DC stick welders? DC welding offers advantages over AC for most stick applications, including: easier starts, fewer arc outages, less sticking, less spatter, better looking welds, easier vertical up and overhead welding, easier to learn how to weld and a smoother arc.

DC reverse polarity (electrode positive) provides about 10 per cent more penetration at a given amperage than AC, while DC straight polarity (electrode negative) welds thinner metals better.

AC has advantages if welding on material that has become magnetised from friction, such as when hay, feed or water constantly rub against a steel part.

A DC output won’t work because of ‘arc blow’, where the magnetic field blows the molten filler metal out of the weld puddle. The AC succeeds because AC output alternates between polarities, thus enabling welding of magnetized parts.

A 225 to 300 amp machine handles most anything for the average farm mechanic. In fact, most stick welding procedures require less than 200 amps. To weld material thicker than 3/8 inches (9.5mm), simply make multiple passes — this is what professionals do, even when welding on 1-inch (25mm) structural steel.

Welder ‘duty cycle’ is relevant. Duty cycle refers to the number of minutes out of a 10-minute cycle a welder can operate. For example, Miller’s Thunderbolt XL creates a 200 amp DC output at 20 per cent duty cycle. It can weld continuously at 200 amps for two minutes, and then must cool for eight minutes to prevent overheating.

Duty cycle and amperage are inversely proportional. Operating at only 90 amps, the Thunderbolt has a 100 per cent duty cycle, meaning you can weld without stopping. Exceeding the rated duty cycle can damage the welding unit.

The standard designation for welding rods is printed on the end of the stick, if not immediately obvious on the packet. These designations were standardised in the United States by ASTM and WIA, with the first two digits representing the metal’s tensile strength. For example, 60 series rods have a maximum tensile of 60,000psi (415MPa) and the 70 series 70,000psi (485MPa) tensile.

Common electrodes used for general work include 6010, 6011, 6013, 7018 and 7024, each of which has specific properties: 6010 electrodes penetrate deeply, while 6013 electrodes penetrate less.

For much better bead appearance and work on higher strength steels — say for an implement hitch — use a 7018 rod. For better penetration on thick material, grind the joint to a 30 degree bevel (leave a 2mm width land on the bottom of the groove) and make multiple passes.

Alternatively, make the first pass with a 6010 rod, then make a ‘cap’ with a 7018.

The 7024 rod is perhaps the easiest to use. This is also known as a ‘drag rod’, meaning the electrode’s thick flux automatically maintains the correct arc length, which allows you to drag the rod directly along the work piece. That’s pretty handy for better looking welds.

Hard-facing rods can provide impact resistance, abrasion resistance, or both depending on the application. Because the type of rod required depends on the type of soil or material the tool is exposed to, it’s probably better to ask the local welding supplier for advice.

INVERTER WELDERS

|

Inverter welders have several advantages when compared with a traditional welding power supply. Both require a transformer to convert incoming current to suitable welding current, but with an inverter welder this can be done more efficiently at higher frequencies.

As a result, the inverter is able to use a much smaller transformer. The result is a very substantial reduction in size and weight.

Power consumption also decreases as the more efficient transformer loses less energy to heat.

It is possible to run these welders on regular single-phase household current due to lower input voltage requirements.

Duty cycle is also considerably higher. The higher the frequency, the less iron and copper needed in a transformer. That reality leads to less expense to manufacture a machine because less material is used.

In today’s world of solid-state electronics, it is simple to convert 60 Hertz incoming power to any desired multiple of 60Hz, transform that power and then convert it to any waveform that is desired, or to DC at the welding electrode.

Inverter welders have very little heat loss in comparison to transformer machines. It gives the less-bulky inverter machine the ability to utilise nearly all of its input current where as a transformer could lose up to 20 per cent efficiency due to heat loss.

What that means to the welding operator is that they are able to maintain an arc in welding circumstances that would cause a conventional transformer welder to make the electrode stick to the work.

A 5mm diameter electrode can be run on an inverter machine and it’s practically impossible to make it stick to the job.

It’s possible to use certain inverter welder units to power all welding processes including stick, MIG and TIG — these are called multi-process welders or three-in-ones.

The higher frequency of the output current and computer software that constantly monitors and adjusts current and voltage during the welding process, produces a consistent smooth arc that’s easier to strike.

On single-phase they do need a 15 amp power outlet. Welding supplies such as electrodes, welding wire and shielding gas typically last longer than when using a traditional welding power supply.

Adjustments to current and voltage can be made to accommodate differences in material composition and thickness, giving the operator tighter control over the welding process.

The reduced size and weight of these welders make them popular choices for applications where a traditional transformer welding power supply would be too bulky or consume too much power.

As a consequence, they are used in machinery maintenance facilities and auto repair shops where cost and space savings are afforded by inverter welders. That makes them ideal for farmers as portable, light-weight units for on-site repairs.

If you’re thinking about buying an inverter, ensure you buy from a reputable supplier that can honour warranty and provide back-up if needed.

Be advised that inverter welders are highly efficient, but will not make up for lack of skill.

TIG WELDERS

|

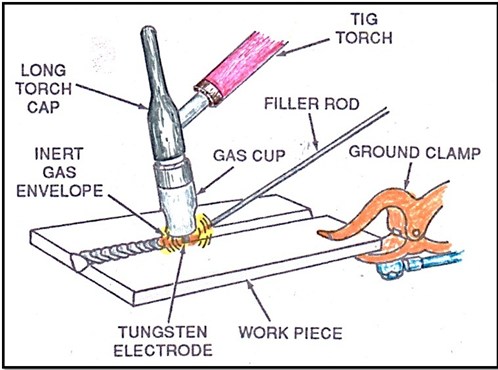

TIG stands for tungsten inert gas — also known as gas tungsten arc welding (GTAW).

TIG welding requires more skill than many other welding forms, but is extremely versatile, capable of joining a huge range of metals in varying thicknesses around the farm.

TIG welding is neat and precise, and can produce a beautifully finished weld bead.

In the TIG welding process, the arc jumps between a non-consumable tungsten electrode and the work piece, generating high temperature. The inert gas shield, usually including argon, prevents weld oxidation. There is no spatter or slag and thin metals are readily joined.

The most obvious difference between a TIG unit and an AC/DC stick welder is the non-consumable tungsten electrode that conducts the welding current. The electrode is secured in the handle by a collet. Shielding gas is directed around the weld by a ceramic nozzle or cup, designed to withstand the intense welding heat.

Different-sized cups are available: smaller cups for smaller welds and assisting access to difficult areas; larger cups improve gas flow and coverage for bigger weld beads.

The beauty of not having to clean up a no-slag weld is tempered slightly by the fact that TIG mandates a clean prepared surface in the first place for quality welds. Any type of foreign matter including moisture or residues of surface cleaning solvents will contaminate the weld.

Apart from skill required with TIG, there are a couple of other considerations:

- Relatively high cost. The investment of from one to several thousand dollars in an AC TIG unit generally can’t be warranted on a farm unless there is a heap of work and a big job that can’t be contracted out. By contrast, however, an inverter TIG is on the order of $400. That’s still twice higher than a beginner needs to spend on a modest stick welder. It’s compactness and ease of striking and running a smooth bead are impressive once the technique having both hands engaged is mastered

- TIG welding is slower than other arc welding methods, so the time cost of TIG welding is comparatively high.

MIG WELDERS

|

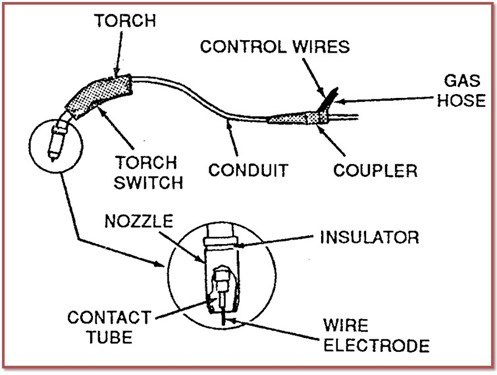

MIG stands for metal inert gas — also known as gas (shielded) metal arc welding (GMAW).

This electric process involves continuously feeding a wire electrode that melts in the arc to form a weld bead. The weld must be protected from the surrounding air by a shielding gas.

A mixture of gases are used, usually including argon.

On the other hand, tubular flux-cored ‘self-shielding’ wires are available, which need no external gas.

In any event, good ventilation in the weld area is essential because of the fumes and slag is formed on the weld that has to be removed between passes or before painting.

MIG welders with solid wire are the more common type used with industrial robots and on heavy thicker work because of the continuous feed electrode wire and automatic arc length maintenance.

MIG weld joints are stronger, more ductile and have less distortion than other welding processes — and are ideal for thin metal work, alloys and aluminium.

Welding wire is not inexpensive though and there’s a bit more to the technique with MIG, like welding meter amps and volts, wire speed and position.

There is the gas-less wire option with MIG that’s a lot cheaper than bottle rental.

In choosing a welder from one of these, arc welding eliminates gas bottles — however, that option is not as nice as running a MIG on gas, but with this method the power supply must be considered — ideally a constant current with very little droop in voltage is needed.

Duty cycle is a consideration — the machine will need to be monitored to avoid overheating. For example, a 200-amp welder with 30 per cent duty cycle should weld for no more than three minutes in 10, allowing seven minutes for cooling.

The inverter welders are great for farm work because they can be lighter, readily portable and have a high-duty cycle.

In all cases, for the best welds, clean work is essential, not to mention wearing the correct safety gear.

GAS WELDING

|

More often ‘oxy welding’ uses a fuel combination of (usually) oxygen and acetylene as the heat source.

A neutral (one-to-one acetylene/oxygen) acetylene flame — the inner cone — temperature is some 3,172C. This primary flame creates a molten weld pool that is protected by the outer flame which prevents contamination of the molten pool that is filled with a welding/filler rod.

The rod is usually made of the same material as the component(s) being welded. Mild steel melts at 1,485C incidentally.

Against the versatility of the farm oxy set, a disadvantage of oxy welding compared with arc welding is the amount of heat absorbed by the part being welded — and that causes distortion.

Excess heat may weaken the area due to changes in the crystallographic structure of the base metal.

On the other hand, the oxy set lends itself to many applications on farm such as brazing, hard surfacing, soldering, heating, bending and metal cutting jobs.

|

Dr Graeme Quick is an international expert in farm machinery. Over the past 40 years he has held senior positions at Iowa State University, CSIRO and NSW Department of Agriculture. He’s also a best-selling author. Nowadays he holds various engineering consultanices and, with his wife, lives on acreage in Peachester in south-east Queensland where they grow cabinet timbers and fruit trees. He can be contacted at g.quick@bigpond.com |