2010 TECNINOX F4329-MD

Finance Estimate

Get my Online Quote »

* # View disclaimer

A quote, details of all fees and charges may be obtained by contacting Stratton via stratton.com.au or calling 1300

STRATTON (1300 787 288).

Features

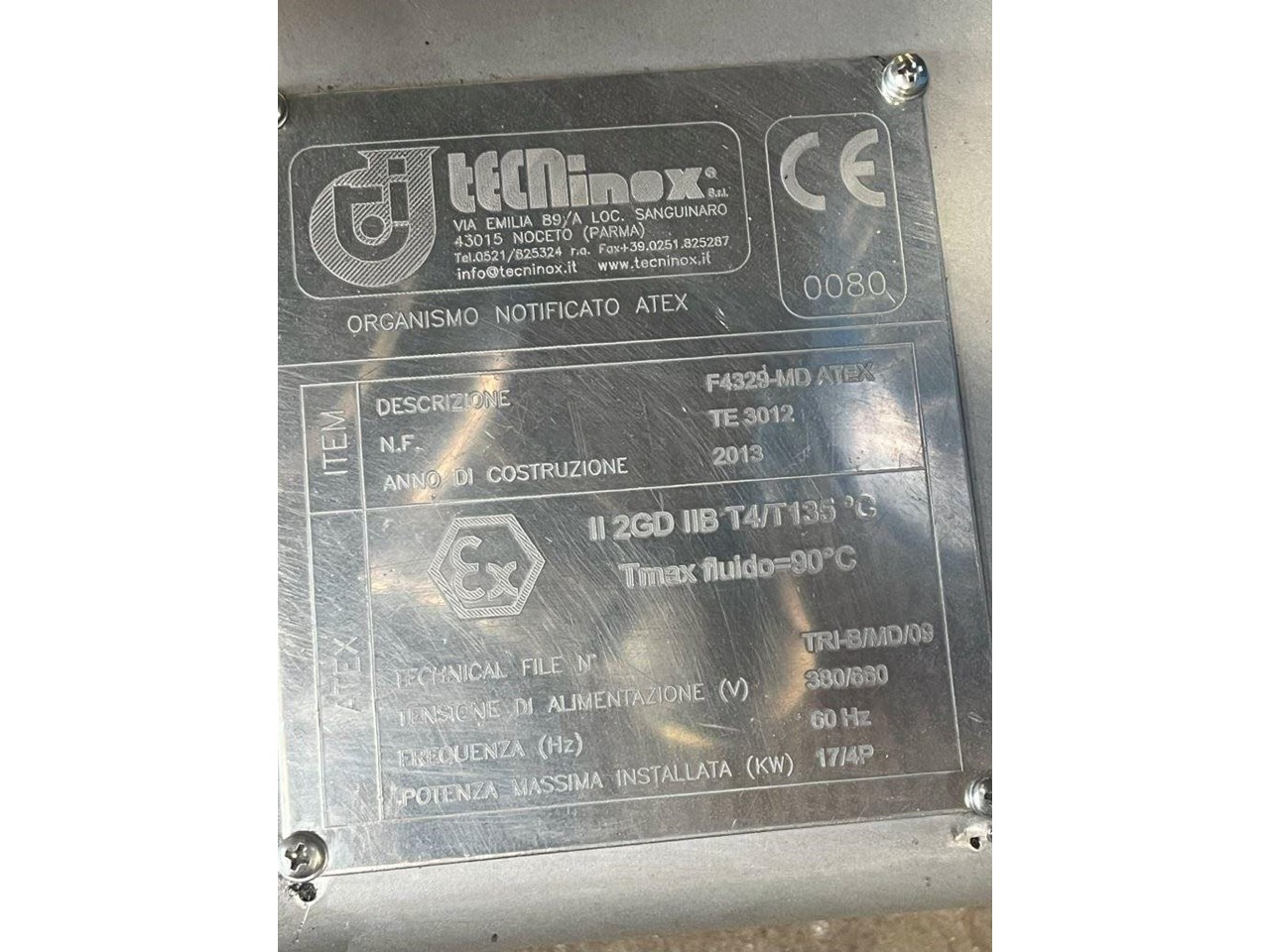

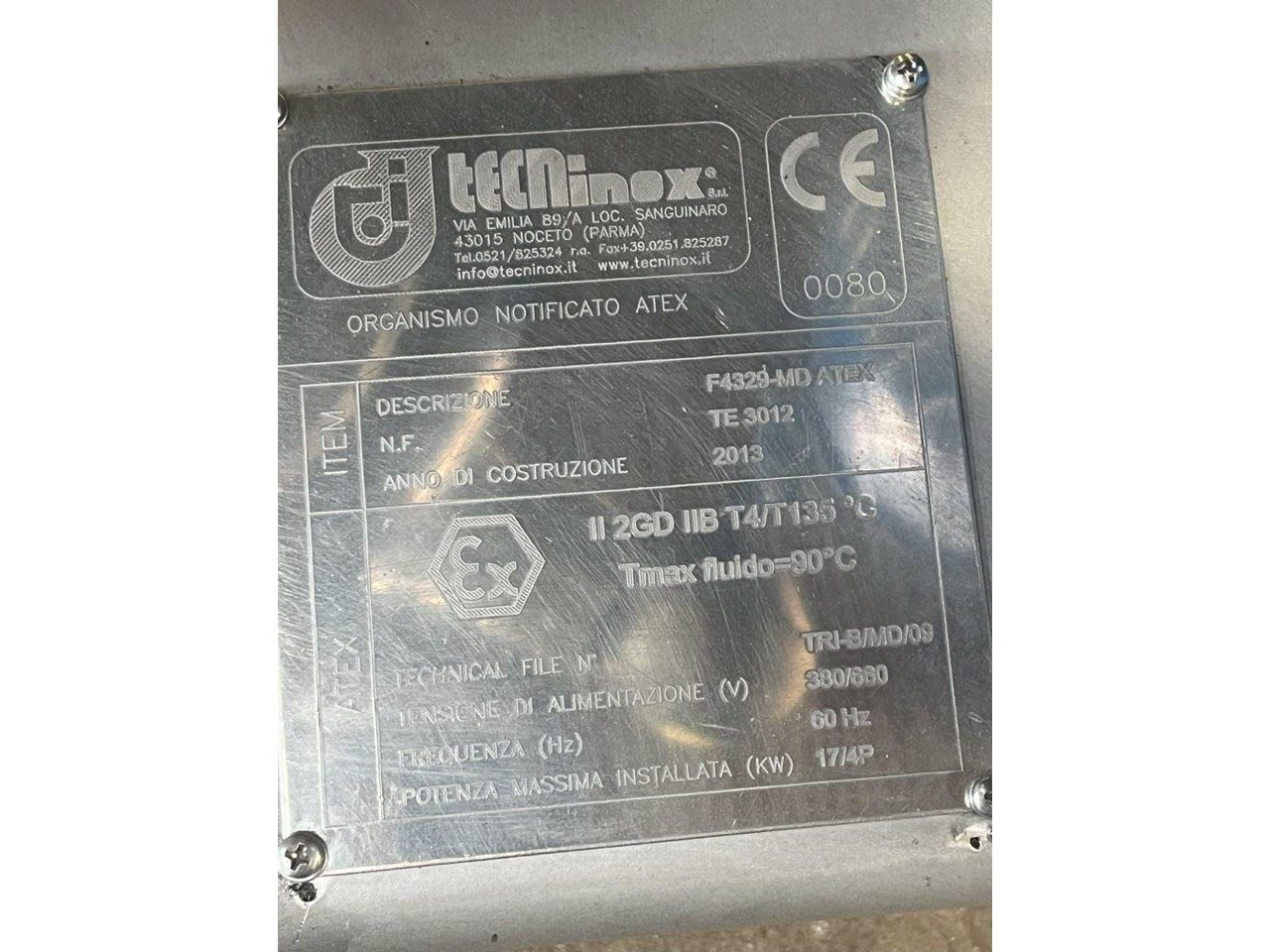

| Title | 2010 TECNINOX F4329-MD |

| Type | Liquid Processing |

| Sub Type | Liquid Mixer |

| Make | TECNINOX |

| Model | F4329-MD |

| Year | 2010 |

| Sale Price | POA |

| Listing Type | Used |

| Stock Number | I.00022543 |

| RefCode | TA1279478 |

Description

TECNINOX - Tri-Blender ATEX Rated Powder/liquid blending system. Fast, thorough and trouble-free blending. Tri-Blenders make it easier than ever to mix powders with liquids, and avoid the time, trouble and lost product associated with reprocessing and pre- and post-blending operations. The Tecninox Tri-Blender is specially designed to thoroughly and efficiently blend powders and liquids, while minimising the air introduced into the process. That means the lumping, foaming and flooding associated with conventional mixing equipment is almost totally eliminated. Unique Tube-in Tube Design. The Tri-Blender is designed to be installed close to the Vessel outlet and at floor level. That's why companies from every process industry are turning to the Tri-Blender to streamline blending applications. The Tri-Blender is designed to integrate easily into your present process system. Plus, its compact size and easy portability means it can be moved or installed virtually any place in the process. Operation Principles. Dry ingredients are fed into the hopper. Vacuum created by the impeller draws the dry ingredients into the blending chamber. As the dry ingredients are added through the hopper, liquid is simultaneously pumped into the head of Tri-Blender. The diffuser tube separates powder from liquid until they are fed into the blending chamber. Applications: - Dairy - powdered milk, butter-milk, ice cream mix, whey protein - Food - pudding, chip dip, pizza sauce, stabilizer addition, powdered egg, starch and gum - Beverage - concentrate, flavor addition, vitamin drinks - Personal Care - soap blends,lotion, cosmetics, hair gel, tooth paste - Chemical - herbicide agent, film solution, fertilizer, biodiesel - Pharmaceutical - active ingredient blends, cough syrup, tablet coating Model Number: F4329-MD ATEX. ATEX Rating: II 2GD IIB T4/T135degreesC Tmax fluid=90C Dry Ingredient Capacity: 159 KG/MIN. Flow Rate: 34,000 L/H. Powder Inlet: 4 Inch Liquid Inlet: 2 Inch Liquid Outlet: 3 Inch Powder inlet has a pneumatic control valve. CEMP Electric motor, 3 Phase, 380/660V, 37.15/21.45A, 17.25kW, 60Hz, 1760RPM, EX rated Motor. Impeller speed approximately 3500 RPM.