New ANCA grinding machine control system all but guarantees a smooth finish

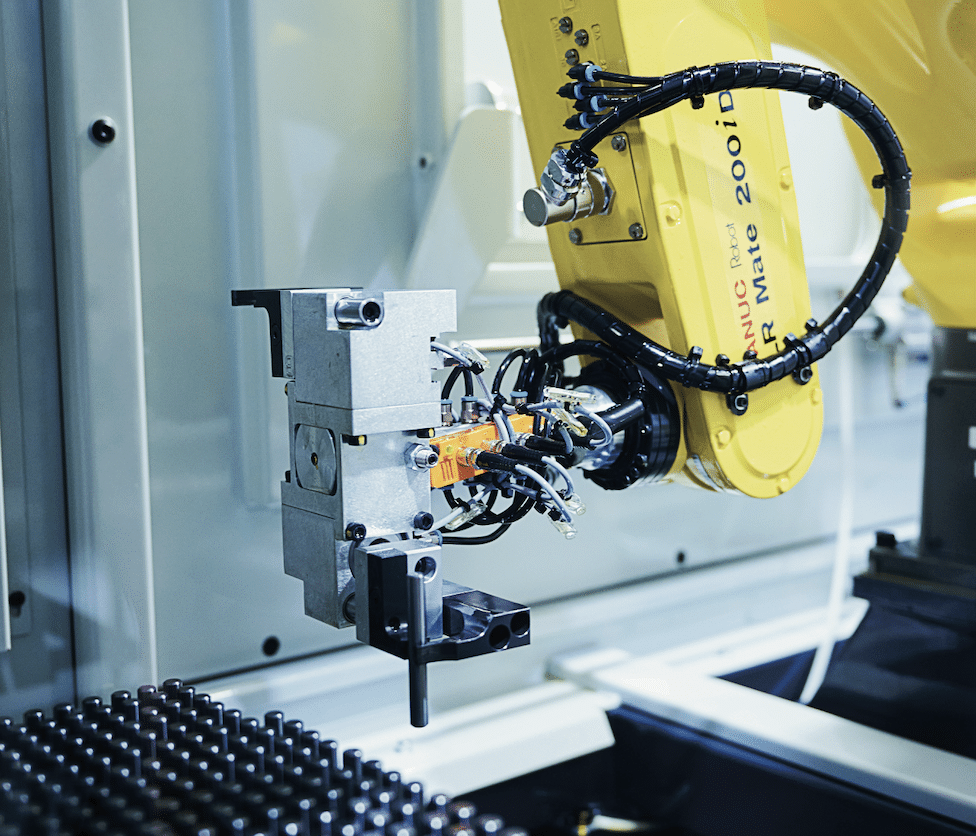

Melbourne-based CNC grinding machines developer ANCA has developed a new nanometre control system which it says

is setting new standards in precision machining.

Installed on its new M7 Ultra machine, ANCA says the system will help manufacturers produce a premium range of cutting tools with “the utmost precision”.

“This cutting-edge technology enables silky smooth movement of all linear and rotary axes, resulting in exceptional surface finishes on cutting tools,” it says.

ANCA’s nanometre control system utilises a state-of-the-art servo control algorithm, allowing for the smooth axis movement that is vital for achieving high quality surface finishes on cutting tools.

Combined with its nanometre-level measurement capabilities, the algorithm ensures ultra-fast response to internal and external disturbances, such as linear rails, bearings or friction.

ANCA says that one of the system’s best features is its ability to reduce reversal errors to the nanometre scale when an axis changes direction during grinding.

Eliminating the reversal marks that could degrade the quality of the tool helps also reduce the need for secondary operations such as finishing or sparkout, resulting in improved cycle times and increased productivity when high-quality cutting tools are being produced.

“By leveraging ANCA’s expertise and deep industry knowledge, the Ultra range of machines equipped with this revolutionary control system opens up new possibilities for the grinding industry,” ANCA says.

“This holistic approach ensures optimal design and functionality, resulting in an unrivalled level of accuracy, performance, and tool life.”