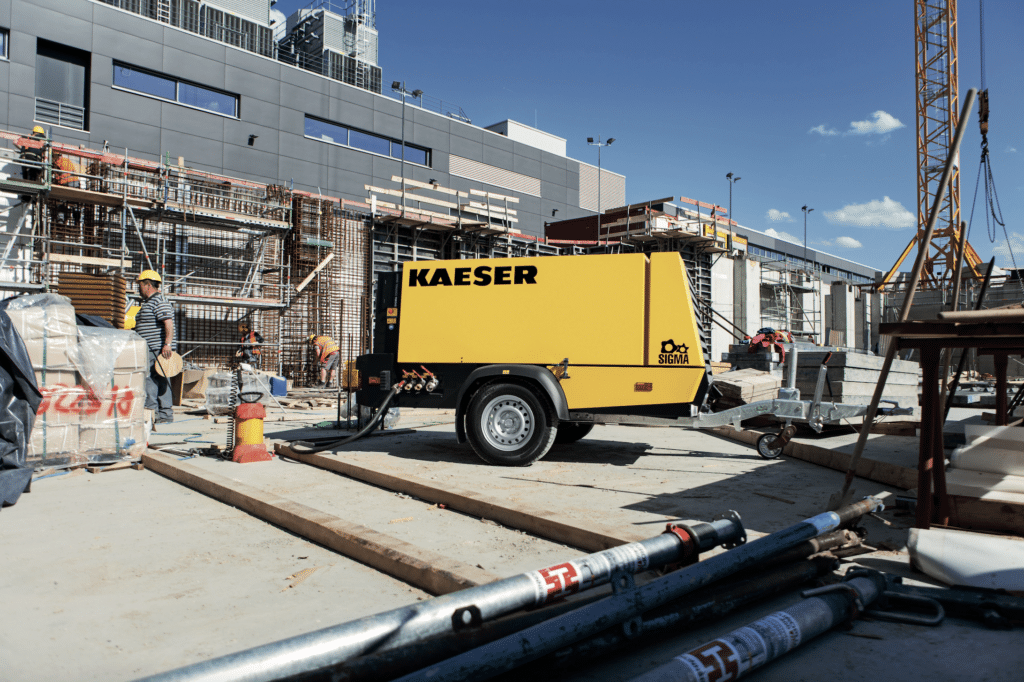

Efficiency and dependability are mainstays of Kaeser’s Mobilair range of portable air compressors – and its diesel-powered units are ideal for working across industry

Manufactured at the Kaeser head- quarters in Coburg, Germany, the Mobilair portable air compressor range comprises a variety of sizes and power sources – with petrol, diesel and electric motors available.

With flow rates from 0.85 to 45.8 cubic metres per minute, and pressures of 7 to 15 bar, there is a compressor to suit all applications.

Located in the middle of the Mobilair range are the 8.6bar M 122 and 8.6 or 10bar M 123 units, currently available for immediate delivery within Australia.

Respectively, the units have maximum flow rates of 11.1 and 11.4 cubic metres per minute, with 83kw and 88kw Deutz engines and operating weights of 1865kg and 1945kg.

The M 122 features mechanical engine management and a traditional control panel, while the M 123 boasts an electronic engine management system and Kaeser’s Sigma Control Smart compressor controller as standard – it is available as an option for the M 122.

The Sigma Control Smart compressor controller has an operating mode display, intuitive user interface and system diagnostics to ensure optimised compressed air availability, fuel efficiency and efficient exhaust air management.

The economical, diesel-powered air compressors come with a braked trailer and a height-adjustable chassis, making them convenient to move onto and around worksites, while their large enclosure doors make components easily accessible for service.

Both units have 170l diesel tanks – sufficient for an entire shift without the need to refuel, though an automatic shutdown feature is activated when the fuel levels become too low or in case of a fault.

The ability to switch over manually from idle to full load operation ensures a reliable, gentle start when operating the machine in cold conditions. Standard units are rated for ambient temperatures between -10 and +50° C.

An aftercooler and a centrifugal separator ensure cool, condensate- free compressed air, while Mobilair’s anti-friction bearings and Sigma Profile rotary screw airend are designed to help the compressor save energy.

The more efficient airend is available across the Mobilair range, with some of the smaller models available with either rotational moulded polyethylene or metal enclosures.

Optional features such as a closed floor pan allow the compressors to be used in environmentally sensitive zones, while a spark arrestor and engine shut-off valve means they are suitable for use in refineries and other places where a compressor might take in combustible gases.

Certain Kaeser compressors are available with 6.5 kVA generators to provide auxiliary power without needing an additional machine on site.

Powered by electrical power connections, Kaeser’s electric drive makes those Mobilair compressors ideal for use in low emission and noise protection zones such as tunnels, excavation pits and city-centre sites, as well as indoor operations.

In recent years, many industries have suffered supply issues and prolonged freight delays, a circumstance which has almost become a ‘new normal.’

However, in a change of events, there are M122 and M123 units now available from Kaeser’s Melbourne base.

To find out more, contact Kaeser at au.kaeser.com or call 1800 640 611